Water jet cutting provides designers with a level of freedom that no other cutting method can match. Water jet cutting can cut irregular forms from nearly any material with outstanding precision and edge quality, and it has a wide range of applications.

Water jets can now cut curves, straight cuts, internal holes, and letters in a fraction of the time it took to cut them by hand. These are the benefits of water jet cutter.

Why You Should Get A Water Jet Cutter

Increased Cutting Flexibility

Simply said, if a water jet can’t cut your material, it generally can’t be cut at all. One of the main reasons the water jet is such an appealing option is its ability to cut nearly any task your clients want efficiently.

Water jet cutters cut all of the following items daily:

- Aluminum: Tipper trailers, boat makers, aircraft components, and general manufacturing

- Automotive: Insulation, carpets, headlining, and trimmings

- Hardened Steels: Bisalloy, military hardware, and armor plating

- Ceramics: Porcelain, tiles, and wear liners

- Granite and Marble: Vanity tops for kitchens and bathrooms, memorials and monuments, and ornamental flooring

- Glass: Glass art, splashbacks, and doors

- Plastics: Composites, fiberglass, kevlar, and polyethylene

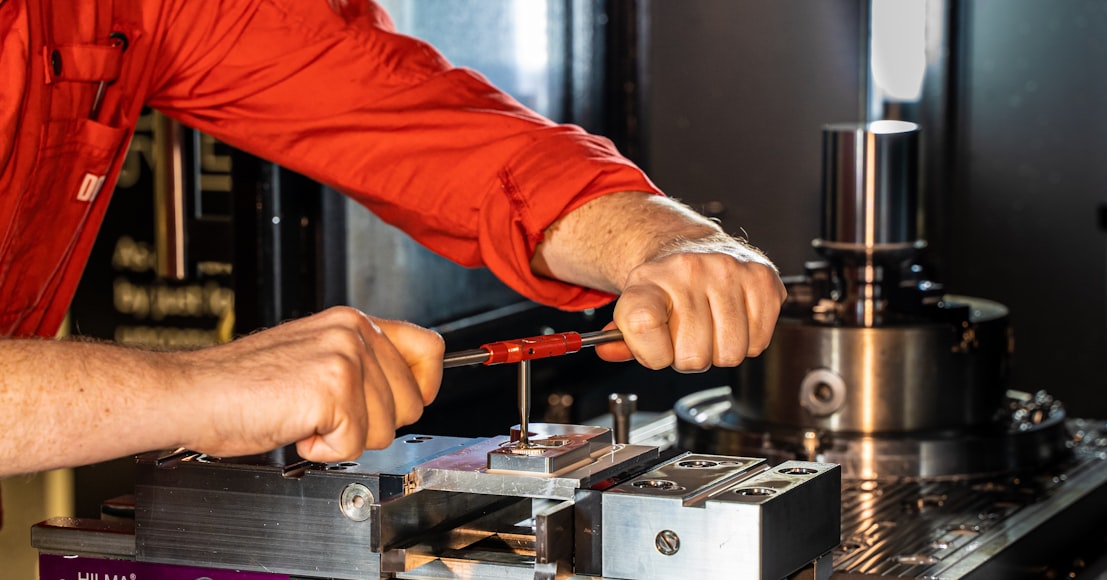

Exceptional Edge Quality

One of the most crucial reasons why designers choose water jet is the edge quality. The water jet creates a smooth, burr-free edge. In many situations, a water jet removes the need for secondary finishing, saving you time and increasing your workshop’s productivity.

Accurate Internal Cutouts

A water jet is a highly versatile cutting tool with cutting precision ranging from 0.038 to 0.2mm, which is why it is utilized extensively in various sectors for complicated designs and operations requiring high standards.

Cost-Effective and Efficient

Water jet is your best option if you want a technology that can offer outstanding edge quality with little or no extra edge treatment and the versatility to cut nearly any type and thickness of materials.

Cold Cutting

Water jet cutting is a cold cutting technique that eliminates heat distortion and hardened edges. This is very useful for complicated metal manufacturing and objects needing further machining after being cut.

Applies to Any Shapes and Thickness

A needle-sharp cutting stream is created by mixing high-pressure water with abrasive to cut nearly any form or thickness. Laminated materials such as aluminized composite panels and rubber-lined wear plates are examples.

No Tool Changes

Cut all of your materials on one machine. When moving from one product to the next, the water jet employs the same tool. To match the kind and thickness of the material, just change the feed rate to the proper speed.

Need A Reliable Water Jet Cutter?

Whether you’re new to water jet cutting or you’ve been using it for a while, it’s always vital to be aware of the advantages of this technology. Explaining the five benefits of a water jet cutter and how they may help you make a sound business decision.