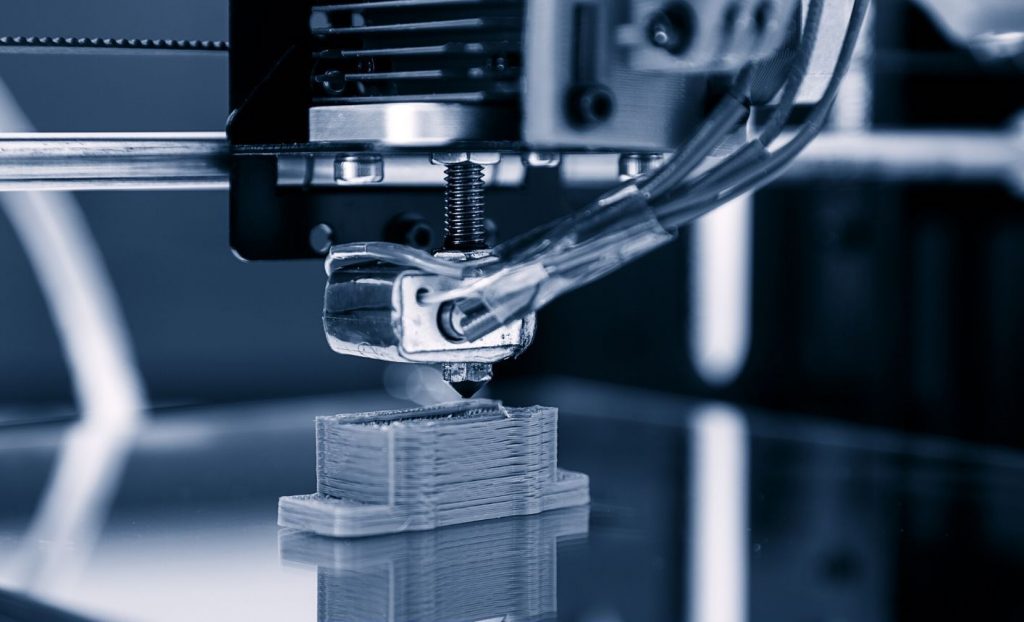

3D printing methods– which utilize electronic versions to produce physical gadgets from materials such as plastic– offer a fantastic chance for medical tool producers and permit the manufacture of cheap, tailor-made gadgets as needed by people and doctors.

Nevertheless, 3D printing innovation is still comparatively new. It has recently been taken on in the production side of the medical tool sector. Right here are pros to 3D printing for makers of medical gadgets.

3D Printing Sydney: 3 Advantages of 3D Printing Medical Tools

Personalized Medical Devices and Patient-Specific Implants

3D printing could produce medical gadgets and custom-made implants for a patient’s particular physiology, making it much more efficient compared to a mass-produced gadget. Customized surgical treatment- as well as patient-specific printed implants and tools, are currently being utilized in knee surgical procedures, where cosmetic doctors at Yale Medicine have located that they speed up the recovery and minimize personal pain levels.

Given the introduction of this new technology, a couple of makers are already establishing their patient-specific clinical tools. Some substantial patient-specific clinical gadgets growth includes orthopedic implants, external prosthetics, and customizable air passage stents.

In-Time Production Method to On-demand Tools.

The rate of 3D printing could mean that it’s feasible for suppliers to promptly develop tools in reaction to client needs. Traditional implants may take some weeks to create and manufacture, particularly if they have to be tailored for patients. 3D printing is being used to reduce the moment required to make bone grafts to as little as feasible.

Incorporated with the likelihood of customized clinical tools, the just-in-time method permitted by 3D printing can lead to on-demand personal tools. Such components can be a far better suit for clients than the tools they might have to wait for in the past.

The rate and adaptability of this method might assist in decreasing waiting time for the patients and lessen the probabilities of problems that might happen due to delayed or inaccessible medical gadgets.

Rapid Medical Prototyping

3D printing is usually less costly and sometimes quicker than typical production approaches, suggesting that suppliers can rapidly make, print, and examine medical tool prototypes.

Some medical tool businesses already utilized 3D printing to swiftly develop and examine medication shipment tools, like injectors and inhalers. Such tools should be both comfy and easy to use. Frequently, producers can only inform if a design is ergonomic and constructed for human usage with duplicated testing.

Old design and production approaches may require weeks to generate a new model. With 3D printing, it’s much faster to repeat previous styles– 3D innovation permits a model to be intended and published in just a few days.

Clinical tool manufacturers can benefit from 3D printing Sydney services in various ways. This innovation permits more affordable manufacturing prices, patient-specific devices, and a just-in-time manufacturing method.