In today’s modern world, it’s no longer surprising to hear about new discoveries and technologies that make our lives easier and better. These new technologies have revolutionized our world in countless ways.

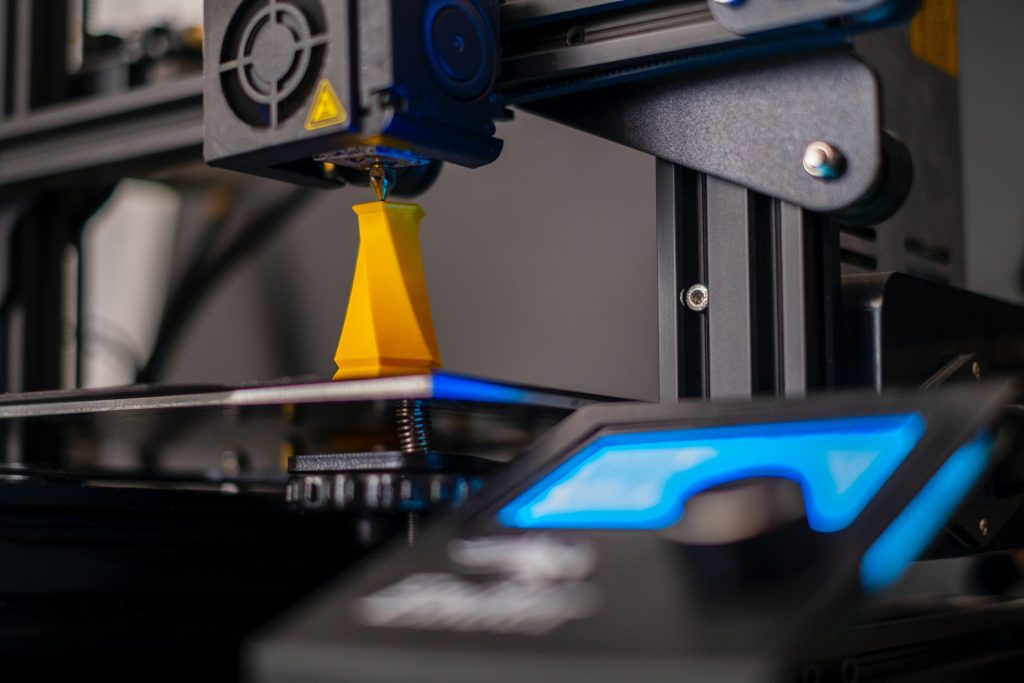

One of the revolutionary technologies currently making a difference in our world is 3D printing. Also referred to as additive manufacturing, this technology is an additive manufacturing process that creates a physical object from a digital design through material layering.

Simply put, this process works by laying down thin layers of 3D printing materials such as plastics, metal, or ceramics and then fusing the layers together until the final object is formed.

This technology is rapidly being adopted in various fields and industries, from medicine, entertainment, and fashion, to automotive, aerospace, and architecture.

Why 3D Printing?

Additive manufacturing is expected to play a crucial role as a trendsetter in the years to come. With its unmatched potential to produce any prototype and manufacture different products more quickly than traditional methods, the industrial demand for this technology is expanding globally.

Here are some of the reasons why industry leaders and business owners take advantage of this innovative technology.

Takes Manufacturing to the Next Level

Global manufacturers have seen the potential of additive manufacturing in terms of faster lead times. Decades ago, it took manufacturers more time to create a prototype for sampling and presentation purposes. The traditional process is not only expensive but also takes time.

With the help of 3D printers, product development and the testing stage have faster turnaround times. In just a few minutes or hours, you can now have your prototype in hand.

Capacity to Print in a Variety of Materials

When 3D printing technology was first introduced to the market a few years ago, it could only print on limited materials, which was considered one of its downsides by many. But as the technology continues to evolve, it already has the capacity to print a variety of materials.

One of the significant innovations of this technology was when it started to print using metal. It is the automotive industry that first saw this potential and took advantage of this progress. And later on, other industries started integrating this technology into their manufacturing process.

Today, the people behind 3D printing are focusing on creating 3D printers that will be able to 3D print food and use other industry-grade materials. The applications of this technology in the food industry could provide solutions to problems of food shortage.

Printing of Complex Pieces and Designs

One of the previous challenges that manufacturing faced was the accuracy and precision in producing complex objects. With additive manufacturing, manufacturing objects or pieces with complex geometries and designs has become possible. Any geometric complexity is no longer a problem with 3D printers.

Helps Achieve Better Medical and Dental Care

In recent years, additive manufacturing has been empowering doctors, dentists, researchers, and medical manufacturers to work faster, test more thoroughly and make healthcare more personalized and customized. The benefits and applications of 3D printing in the medical field include personalized patient care, innovation in medical and dental devices, and high-strength and biocompatible materials to improve efficiency.

Wrap Up

Though additive manufacturing is a promising technology and cutting-edge, it still has a long way to go before becoming mainstream. Currently, this innovative technology still has limitations, such as high material costs.

But being the first digital manufacturing technology, 3D printing is exhibiting its transformative nature and has already been altering businesses and industries with remarkable efficiencies.