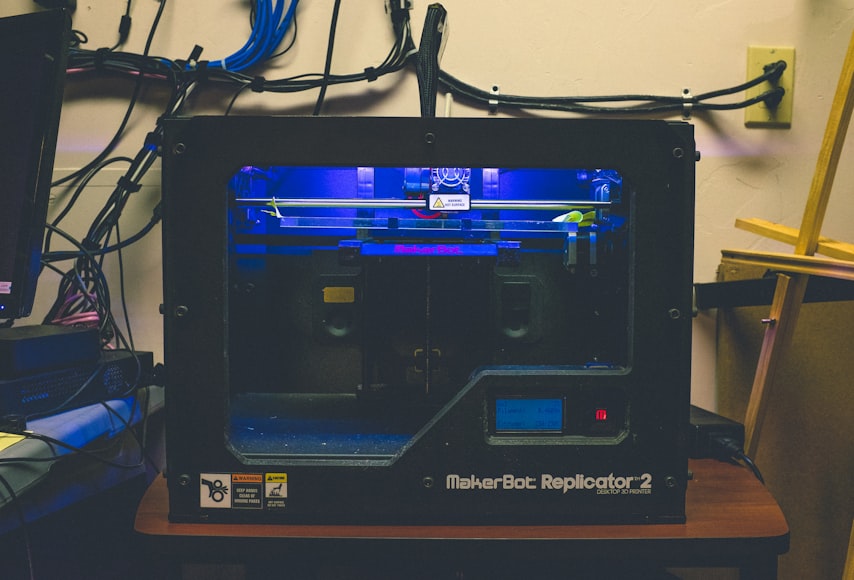

The development of 3D printing is a change in the industrial sector. You have checked out advances in three-dimensional printing and the many advantages. Yet have you used an item that is printed? Do you know anybody that has made use of or seen this item?

Challenges In 3D Printing Brisbane

Material and Equipment Expense

3D printing modern technology is developing for this reason. The tools and also material expenses are high, and many top-quality printers and raw materials should be imported from other nations. Greater price constructions for 3D printers and materials make the access factor much more costly than other innovations such as injection molding, CNC machining, etc.

If the price of 3D publishing a product is very high than other alternatives, customers will certainly go with the next choice offered. The greater price could be acceptable in different countries because of high workforce expenses, yet the same cost structure won’t operate in the market.

Absence of Official Requirements

As 3D printing is in the preliminary phases of development, there is an absence of standards. Several jobs are needed in such a direction because the absence of criteria in printing is obstructing its adoption. The adjustment would certainly ensure uniformity and top value for products developed using 3D printing Brisbane, which will urge its adoption.

Absence of Community

There are some service providers for printing services. Such carriers are mainly stand-alone stores, and many do not have solid online visibility. Some may be given some 3D printing technology or limited choice of materials, so the total environment does not have. These suppliers are required to be together on a platform to give extensive 3D printing remedies.

The 3D Printing Market is Monopolistic

The OEM that assemblies the 3D printers also generates materials for the makers. As a result of this syndicate, consumables are pricey. The sector should be democratized. For instance, HP has democratized machines for other people to establish their very own materials.

3D printing materials have to be standardized. Given that basic material norms are not present, firms are required to establish and satisfy quality requirements not just for the products but for the materials and procedures.

Lack of understanding of 3D Printing Procedures

For most customers, 3D Printing means FDM innovation. Awareness is absent regarding various 3D printing innovations and also utilize cases for them. One must inform the users regarding the capacity of the technologies and exactly how they can be utilized for their items.

Designing for Additive Production

Companies today make a component in 3D printing using the guidelines of conventional production. Consequently, although the element is produced faster and in fewer amounts, the component style is not as effective as it might have been since the component was never developed for Additive Production (AM).