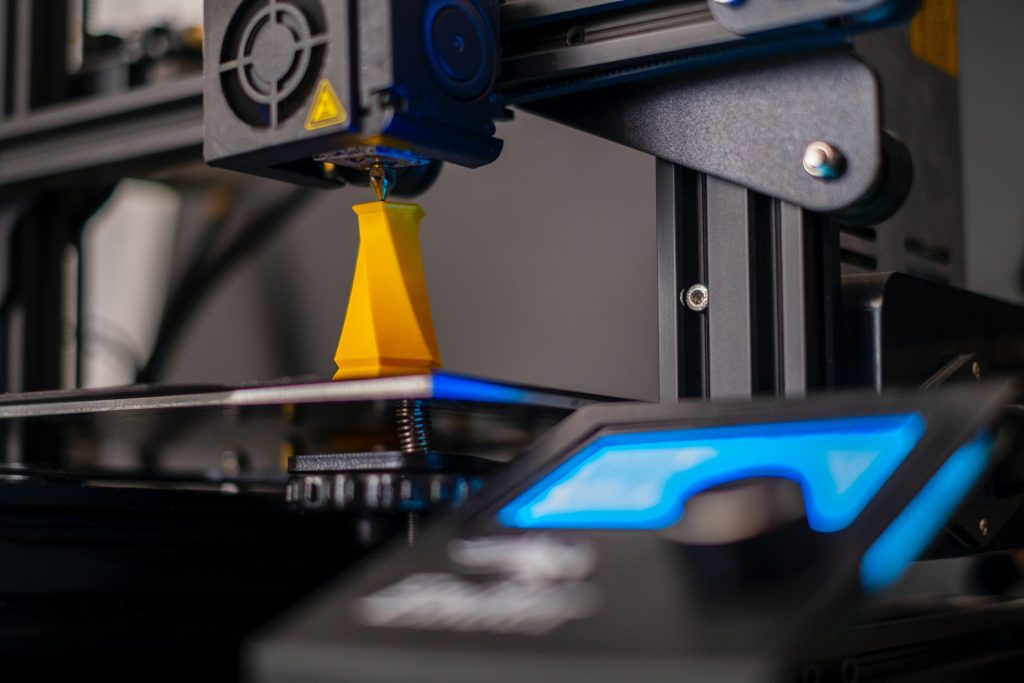

Conventional manufacturing is tested by the development of additive manufacturing or three-dimensional printing. Developers, companies, and business owners are using the advantages of 3D printing to satisfy the ever-altering demands of their tasks and products.

Below are the essential advantages that might save you and your firm lots of money and time by replacing early or last shot molding.

3D Printing Versus Injection Molding

Getting in Low Quantities

Having the capacity to order over a solitary unit is helpful for anybody seeking to establish, customize, and examine a brand-new or an existing component or product. Shot molding multiple components need a different mold and mildew for every, which is prompt and pricey. The effectiveness and speed of additive production permit individuals to obtain several pieces or forms faster compared to any conventional manufacturing would certainly allow. Buying in reduced volume permits you to try, examine, and bring your products to market or components being used quicker.

Permits Several Item Changes

Injection mold generally costs $12,000 to make. When responses come in, and item adjustments are required, you will spend significant time and money producing new molds to make these modifications. With additive production, this trouble becomes outdated. The quick turn-around time and inexpensiveness of 3D Printing would let you test, gather comments, and determine and modify as many variants required for the final product. With 3D Printing, there is no preliminary overhead to make a product as with shot molding.

As Needed Manufacturing vs. Holding Huge Supply

Order what is needed, as you require it! Startups, Creators, and big businesses face supply obstacles, remaining on lots of dollars worth of stock and products waiting to be sold. With 3D manufacturing, you can control the inventory levels and when supply is needed it could be established, published, and in your own hands.

Expense Breaks with Enhanced Quantity

3D printing competencies permit you to purchase any number of produced pieces for your project or business requirements. With shot molding, the introductory price is exceptionally high, and at approximately 1,000 components, you will certainly have a recovery cost point competitive with 3D Printing. Suppose you’re aiming to order and also create in smaller-sized quantity runs. In that case, 3D Printing will undoubtedly be one of the most budget-friendly and reliable solutions with its low advance overhead.

Make Parts Too Intricate for Injection Molding

When seeking to transform the suggestion in your head into an actual item or component, the intricacy of a part can establish which production route to take. Features and objects with a facility or organic angles, shapes, and sizes are best and competently made using 3D Printing compared to injection molding.

If you have been having the dilemma of determining which is better- whether 3D printing or injection molding, hopefully, the information above has shed some light so you can make a better decision.