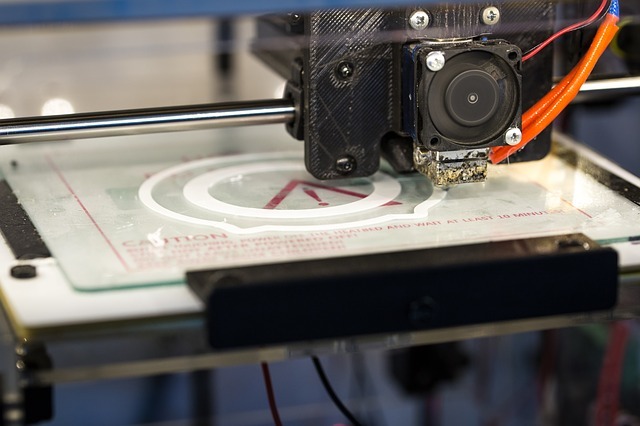

Newcomers to 3D printing could feel overwhelmed by the numerous choices available. A Stratasys 3D printer is offered at a variety of price points, with differing levels and technologies of sophistication. For that reason, there is not a single “best” printer for a task – it will depend on your application requirements and utilization requirements. Below we have laid out the crucial elements to think about when purchasing a printer for the very first time.

Stratasys 3D Printer Buying Considerations

Price

There is a 3D printer for almost every budget. They tend to be probably the smallest on the marketplace, as well as have lower print documents reliability.

Mid-range printers provide elevated reliability as well as print quality, making them well known with educators.

High-end printers provide probably the highest print quality and dependability on the market. They are engineered to be well-suited, accurate, and fast for a range of potential programs, from manufacturing to consumer goods.

Use case

Some systems are better suited for manufacturing uses like functional assessment and tooling, while others are much better for consumer goods or maybe design applications. At Stratasys, you will discover that FDM technology is mostly used for components that have to be strong and durable, while PolyJet engineering is much more frequently used for parts that call for color as well as texture realism.

Speed

Determined by the preferred program, the print pace may be a crucial component. Rapid prototyping or even factory floor programs, for instance, depend on the efficient and fast part output to keep lead times quite short.

Resolution

Resolution refers to the amount of information that a printer is able to achieve. The overall quality of printed documents is driven by the horizontal resolution, and that is probably the smallest movement the extruder is able to make across the XY axis, as well as the vertical resolution, which will be the minimum level thickness the extruder is able to produce. A smaller resolution indicates much better detail in the last part.

Durability

As with some other types of technology, a few printers have an extended shelf life than others.

The planet of printing does not need to be intimidating. This infographic allows you to check out the most crucial parts of an industrial printer created for the business space: the Stratasys F120.

While certain kinds or hobby printing of prototyping may just need one or two textiles, you may need a far more flexible printer for much more advanced uses. Some printers are agreeable with a wider assortment of substances, while others include multiple print heads for much more complicated designs.

Environment

It is essential to think about the environment which is going to house the printer, as it is able to put restraints on other factors and size. For instance, a printer that runs loudly could be disruptive to individuals running close by. Search for a printer that is been specifically engineered to reduce noise levels. For business environments where space is an issue, desktop computer 3d inkjet printers are likely to be smoother and more compact than their much more manufacturing counterparts.

Print size

For hobbyists or beginners, a big build plate likely is not a priority. Nevertheless, in case you intend to make use of a printer for industrial applications and end-use parts, the capability to print larger areas might be beneficial. Bigger build plates allow huge components to be printed everything at once, conserving the manufacturing period.

This list is not exhaustive, obviously. You might have various other priorities specific to the business and desired application. Looking at these basic elements, nonetheless, will assist you in determining the perfect printer for you personally, whatever the application is.

These printers are made in a range of sizes as well as price points, like the F120 desktop computer 3d pt2730.